TORONTO, Dec. 20, 2024 (GLOBE NEWSWIRE) — Giyani Metals Corp. (TSXV:EMM, GR:A2DUU8) (“Giyani” or the “Company“), developer of the K.Hill Battery-Grade Manganese Project in Botswana (“K.Hill” or “the Project”), is pleased to provide an update on the commissioning of the Demonstration Plant (“Demo Plant”) in Johannesburg.

Highlights:

- The Demo Plant is nearing completion of commissioning, and the team continues to work determinedly towards first production of battery-grade high-purity manganese sulphate monohydrate (HPMSM) before year-end, but due to recent events, production may occur in early Q1 2025, due to the impact of the following:

- Power outage from an isolated incident of vandalism and copper cable theft at an Eskom key point substation on December 11.

- Water supply was consequently unavailable to the Demo Plant from December 12 to December 17.

- Unexpectedly slow progress in commissioning the control system.

- The power outage directly impacted the area of Krugersdorp, South Africa and additionally impacted the local water supply and thus the ability to run the Demo Plant. Water, which is critical for the commissioning process, was unavailable to the Demo Plant from December 12 to December 17, and this has impacted progress.

- The water supply to the Demo Plant was reinstated midday on December 17, following which the operations team implemented a 24-hour recovery procedure to flush and clean the crystallisers after the extended stoppage.

- One of the key objectives of the Demo Plant is to identify issues and improve the design, build and ramp-up of the Commercial Facility, which is planned for construction in Botswana adjacent to Giyani’s extensive, 100% owned manganese oxide ore sources.

- Prior to commissioning and during the process, the team has implemented mitigating adjustments which have also impacted the timeline to production from the Demo Plant, including the unexpectedly slow progress in commissioning the control system, mentioned above.

- The transition into full process flow hot commissioning and production remains imminent, now that full utilities, including power and water, have been restored to site. Demo Plant product samples will be provided to offtakers for qualification trials early in Q1 2025, enabling indicative terms in 2025.

Charles FitzRoy, President and CEO of the Company, commented:

“Giyani’s Demo Plant is progressing through the commissioning phase, and the team continues to work determinedly towards first production of battery-grade manganese. Whilst we are targeting first production of HPMSM this month, delivery in early Q1 2025 is likely. This is due to the recent unforeseen external impacts from power and water availability in Krugersdorp, South Africa, where the plant is located, in addition learnings identified and mitigations implemented as part of the normal commissioning process.

Whilst the disruption from power and water outage has now been resolved, the ongoing learnings will be leveraged for the construction of the main plant in Botswana; fine-tuning the process now will have demonstrable operational and cost benefits when we reach construction of the main Commercial Plant, and puts us on firmer footing for a successful and smooth ramp-up. These adjustments further endorse the strategic decision made to construct a Demo Plant at a 1:10 scale to the planned Commercial Facility, as this significantly de-risks the final Project.

The Demo Plant is an essential component in Giyani’s long-term strategy to deliver high-purity battery-grade manganese to the EV market. This production capacity establishes a strong foundation for Giyani to engage with potential offtake partners, as the continuous process flow of the Demo Plant will allow the team to target steady-state operations over extended periods, consequently proving Giyani’s ability to produce consistent battery-grade manganese and satisfy offtake requirements. This continuous operation at pre-commercial scale also provides critical information for understanding how the Commercial Plant will respond, further de-risking the Project.”

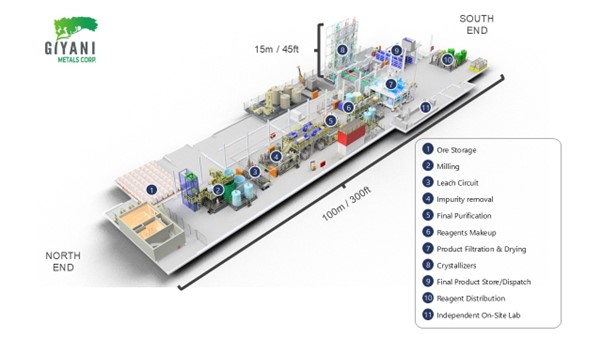

Figure 1: Demo Plant Overview Looking North

Power and Water Outage

The power outage impacted the local municipal water systems in the Krugersdorp region of South Africa where the Demo Plant is located. Whilst the power outage was rectified within 24 hours, the water outage had a more significant impact as multiple industrial and residential zones ran dry simultaneously. These events coincided with extended maintenance works on multiple water systems.

Whilst such incidents are not uncommon within the South African context, this is the first outage that has impacted the Demo Plant.

Water supply was reinstated on December 17.

Without water, commissioning work on site was restricted to areas where water could be recycled and reused. The boiler, which requires fresh water to generate steam, was temporarily shut down. This resulted in a delay of the C4 Hot Commissioning of the crystallisers which was underway at the time of the outage.

Demo Plant Construction and Commissioning Update

The construction of the Demo Plant, which consists of nine Process Modules (each a self-contained process system within a fixed frame) is largely complete. Full construction completion is due within the next week.

Since the news release (“NR”) dated November 14, 2024, commissioning continues apace. Various parts of the Demo Plant are now in the C4 phase, whilst other areas are C3 complete and waiting for first reagent delivery.

Whilst C4 commissioning is typically undertaken on a broader process level, Giyani saw an opportunity to pre-emptively work with the crystallisers in isolation and gain important information and learnings ahead of the availability of the full process flow.

The hot commissioning of the mill, leach, and impurity removal process areas is expected to commence following the delivery of first-fill reagents, which is imminent.

The filter presses used for various solid/liquid separation stages are progressing rapidly through C2 and C3 commissioning, and will be fully commissioned as soon as slurry is available from the upstream processes.

Figure 2: The Newly Commissioned HMI for the Filter Presses

The Demo Plant laboratory, independently installed and operated by Quality Lab Services (QLS, a Minopex company) is nearing full operational capacity, with only the calcination furnaces yet to be completed. The key instrumentation of ICP-OES and XRF are both fully operational and the first sets of full analytical assays have been completed.

Stages of commissioning:

- C1 – Full mechanical completion (individual Process Modules)

- C2 – Dry testing, direction testing, loop testing (individual Process Modules)

- C3 – Cold/Water Commissioning, software testing (individual Process Modules)

- C4 – Hot Commissioning with reagents and steam (typically full Process)

- C5 – Production Ramp-up (full Process)

Figure 3: Onsite Independent Lab – Preparation Area

In addition to progress at the Demo Plant, concurrent metallurgical test-work is underway to further optimize the flowsheet. Giyani is focused on further reducing reagent use and improving both the operating cost and carbon profiles for the Commercial Plant, planned for construction adjacent to Giyani’s extensive 100% owned manganese oxide ore sources in Southern Botswana.

The Demo Plant is designed at a scale factor of approximately 1:10 to the planned Commercial Plant. This provides robust and reliable scale-up from the Demo Plant data when the Commercial Plant is implemented. To illustrate, the leach tanks have a 60cm diameter in the Demo Plant and this is expected to be 8-10x larger at approximately 5m in the Commercial Plant.

Figure 4: Demo Plant Render

Demo Plant Operational Overview

The development of all process plant standard operating procedures (“SOPs”) is complete and Minopex will continue to refine these procedures to ISO International Standards. As the Demo Plant is a direct copy of the anticipated Commercial Plant, at a 1:10 scale, the overall operating requirements and system requirements are very similar. Alongside the engineering, commercial and research benefits of the Demo Plant, the availability of mature SOPs will facilitate a smooth transition to full-scale commercial production.

The independent, fully ISO-certified laboratory will allow commercial-level metal accounting and provide rapid assay turnaround times to enable effective operation of the Demo Plant. The laboratory is near complete and is operational, with key equipment such as the ICP-OES and XRF already in active use.

The laboratory, and all the procedures and methods associated with it, can be transferred directly to the Commercial Plant, enabling a tried and tested laboratory set-up available on Day 1 of Commercial Plant commissioning.

Figure 5: Onsite Independent Lab – ICP-OES and XRF Instruments

About Giyani

Giyani is focused on becoming a dominant western-world producer of sustainable, low carbon high purity battery grade manganese for the electric vehicle (“EV”) industry. The Company has developed a proprietary hydrometallurgical process to produce battery grade manganese (HPMSM), a lithium-ion battery cathode precursor material critical for EVs.

The Company has secured financing of US$26m from two strategic partners, ARCH Sustainable Resources Fund LP and the Industrial Development Corporation of South Africa, enabling it to progress the K.Hill battery-grade manganese project in Botswana to construction by building and operating the Demo Plant and completing a Definitive Feasibility Study in 2025.

Additional information and corporate documents may be found on www.sedarplus.ca and on Giyani Metals Corp. website at https://giyanimetals.com/.

Qualified Persons / NI 43-101 Disclosures

A National Instrument 43-101 (“NI 43-101”) technical report including results of the PEA and the MRE can be found on SEDAR+ at www.sedarplus.ca and made available on the Company’s website at https://giyanimetals.com/.

Justin Taylor CEng FIMMM QMR BSc Eng (Chem) is a qualified person, as defined by NI 43-101. Mr. Taylor is the Company’s Group Process Engineer and has reviewed and approved the scientific and technical content contained in this news release but is not independent for the purposes of NI 43-101.

On behalf of Giyani Metals Corp.

Charles FitzRoy, President and CEO

Contact:

| Giyani Metals Corp. Charles FitzRoy, President & CEO |

[email protected] Tel: +1289-291-7632 |

||

| Tavistock, Corporate Communications Tara Vivian-Neal / Josephine Clerkin |

[email protected] Tel: +44 20 7920 3150 |

||

Neither the TSX Venture Exchange (the “TSXV”) nor its Regulation Services Provider (as that term is defined in the policies of the TSXV) accepts responsibility for the adequacy or accuracy of this news release.

Forward-Looking Information

This news release contains “forward-looking information” within the meaning of applicable Canadian securities legislation. All statements in this news release, other than statements of historical fact, that address events or developments that Giyani expects to occur, are “forward-looking statements”. Forward-looking statements are statements that are not historical facts and are generally, but not always, identified by the words “expects”, “does not expect”, “plans”, “anticipates”, “does not anticipate”, “believes”, “intends”, “estimates”, “projects”, “potential”, “scheduled”, “forecast”, “budget” and similar expressions, or that events or conditions “will”, “would”, “may”, “could”, “should” or “might” occur.

Such statements include without limitation: the Company the ongoing construction, commissioning and operation of the Demo Plant, and timing thereof, the completion of hot commissioning, the delivery of product, and entering into offtake agreements.

All such forward-looking statements are based on the opinions and estimates of the relevant management as of the date such statements are made and are subject to certain assumptions, important risk factors and uncertainties, many of which are beyond Giyani’s ability to control or predict. Forward-looking statements are necessarily based on estimates and assumptions that are inherently subject to known and unknown risks, uncertainties and other factors that may cause actual results, level of activity, performance or achievements to be materially different from those expressed or implied by such forward-looking statements. In the case of Giyani, these facts include anticipated operations in future periods, planned construction and development of its properties and facilities, and plans related to its business and other matters that may occur in the future. This information relates to analyses and other information that is based on expectations of future performance and planned work programs.

Forward-looking information is subject to a variety of known and unknown risks, uncertainties and other factors which could cause actual events or results to differ from those expressed or implied by the forward-looking information, including, without limitation: inherent exploration hazards and risks; risks related to exploration and development of natural resource properties; uncertainty in Giyani’s ability to obtain funding; commodity price fluctuations; recent market events and conditions; risks related to governmental regulations; risks related to obtaining necessary licences and permits; risks related to Giyani’s business being subject to environmental laws and regulations; risks related to the Company’s mineral properties being subject to prior unregistered agreements, transfers, or claims and other defects in title; risks relating to competition from larger companies with greater financial and technical resources; risks relating to the inability to meet financial obligations under agreements to which they are a party; ability to recruit and retain qualified personnel; and risks related to the Company’s directors and officers becoming associated with other natural resource companies which may give rise to conflicts of interests. This list is not exhaustive of the factors that may affect Giyani’s forward-looking information. Should one or more of these risks and uncertainties materialize, or should underlying assumptions prove incorrect, actual results may vary materially from those described in the forward-looking information or statements.

Giyani’s forward-looking information is based on the reasonable beliefs, expectations and opinions of the Company’s respective management on the date the statements are made, and Giyani does not assume any obligation to update forward looking information if circumstances or management’s beliefs, expectations or opinions change, except as required by law. For the reasons set forth above, investors should not place undue reliance on forward-looking information. For a complete discussion with respect to Giyani and risks associated with forward-looking information and forward-looking statements, please refer to Giyani’s continuous disclosure documents which are filed on SEDAR+ at www.sedarplus.ca.

Photos accompanying this announcement are available at

https://www.globenewswire.com/NewsRoom/AttachmentNg/27b3cb1a-8429-4656-88f8-0887ab623f6f

https://www.globenewswire.com/NewsRoom/AttachmentNg/e5ca9885-5e2e-40c0-abca-ade7577e9df2

https://www.globenewswire.com/NewsRoom/AttachmentNg/ee384846-d457-4980-8616-ff015e28425e

https://www.globenewswire.com/NewsRoom/AttachmentNg/5269c5c6-7042-41d4-93d6-765eace2c337

https://www.globenewswire.com/NewsRoom/AttachmentNg/81237c7a-b708-4574-86b2-31bf77e81933